MicSurf

Microstructuring of bioinert high performance ceramics by direct inkjet printing to stimulate cell adhesion and cell differentiation

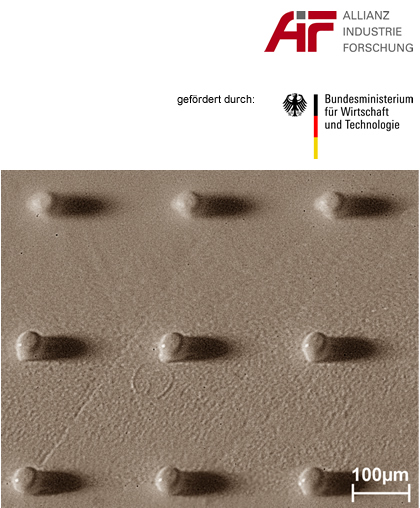

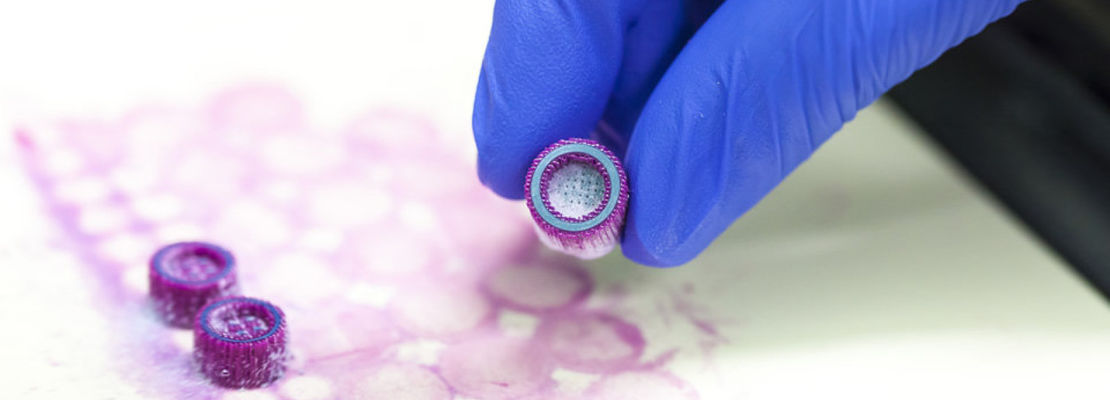

Since many years high performance oxide ceramics are successfully applied in orthopedic surgery and dental prosthetics e. g. as hip joints or tooth crowns, respectively. However, ceramics are not suitable for implants with direct contact to bone because of their bioinert characteristics that limit their osteoconductivity. Strategies of bioactivation to enhance cell adhesion and differentiation at the cell-material interface have to be developed to overcome this limitation. For instance, microstructuring of the material’s surface is known to crucially influence the biological response. Tailoring a defined microstructure such that osteoblast cells are stimulated to form new bone would be a great benefit for the mentioned medical applications.

Therefore, the aim of this project is to generate various microstructured oxide ceramic surfaces by a novel additive manufacturing technique using a direct inkjet 3D printer. The influence of various microstructures on human mesenchymal stromal cell adhesion and osteogenic differentiation will be evaluated aiming to improve bone cell response on structured compared to unstructured surfaces. After optimization of the surface the printing device will be modified to be able to structure also the complex surfaces of arbitrarily 3D shaped components of real implants.

This project is financed by the AIF/BMWi and is realized in cooperation with another academic and ten industrial partners.