StrucSurfCell

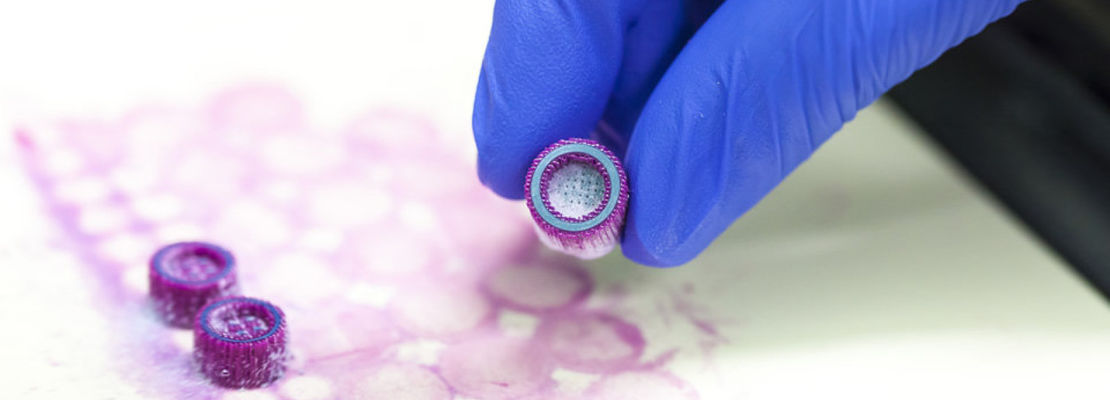

Micro-scale geometrically and metallurgically adapted surface structures of implants for the defined stimulation of the osteogenic differentiation

Metal implants are used for orthopedic applications, e. g. as stems for total hip arthroplasty for decades. Because of its outstanding mechanical properties, especially the titanium alloy Ti6Al4V is used. However, clinical failure of metal implants still occurs frequently. The major cause for this is the so-called aseptic loosening of the implant. An improvement of the osseointegration of such implants by a treatment of the surface, e. g. by etching or corundum blasting, has so far only been described within empirical studies. The influence of the surface chemistry and the surface structure on the initial cell-implant-reaction has not yet been fully understood.

The interdisciplinary research project "StrucSurfCell" is handled in cooperation with an university partner and is supported by the German Research Foundation (DFG). Within this project, the reaction of human mesenchymal stem cells (hMSC) subjected to defined electron beam structured and metallurgically changed titanium alloy surfaces is analyzed. To achieve this, the well-known "SurfiSculpt" process is transferred to the microscopic level. Furthermore, it is supplemented by the possibility to alter the chemical composition of the surface by locally alloying up or leaching material components. Especially the alloying up of highly cytocompatible pure titanium on the mechanically most durable Ti6Al4V alloy is of interest. The influence of the local alloy composition of the microstructured surface on the differentiation behavior of hMSC towards bone-forming cells is investigated in detail.