TracheaPrint

Biofabrication of a prevascularized functional trachea substitute

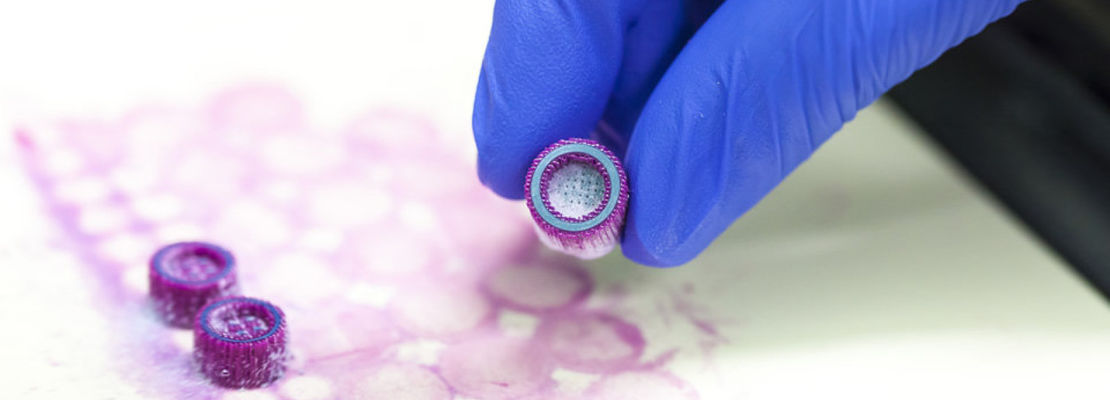

Additive manufacturing techniques applied on the still emerging field of tissue engineering offer attractive ways to process cells and bioactive materials into heterogeneous three dimensional (3D) constructs. Bioprinting, as one representative additive manufacturing technique, refers to printing hydrogel-cell suspensions drop-by-drop generating a heterogeneous, layer-by-layer built object.

The aim of the project is the fabrication of a biomimetic trachea substitute comprised of different hydrogels and cell types. The printed construct should imitate the tubular anatomy of a native tracheal tissue including the cell-laden layers adventitia, submucosa, and mucosa. Furthermore, the native horseshoe shaped cartilage rings are mimicked by a slowly degrading and cell free hydrogel. The respiratory epithelial cells will be seeded on the inner surface of the tubular construct after printing which then is subsequently incubated in a suitable pulsatile bioreactor.

The experimental part of the project comprises the evaluation of different hydrogels with regard to their 3D-printability and cytocompatibility. Furthermore, a cell compatible 3D-printing process will be developed that employs different hydrogels suitable for the purpose. Besides generating a cell-laden, pre-vascularized trachea substitute, the investigation on this project will examine the general suitability, advantages and disadvantages of applying 3D-bioprinting technologies on complex tissue generation.

The project which is conducted together with another academic partner is funded by the German Research Foundation (Deutsche Forschungsgemeinschaft, DFG).